Laboratory and Testing Services

Analysis of Customer Samples

To help you determine what the Cyranose 320, MSEM 160 or any of our other sensing products can do for you, Sensigent can test your samples in our sensory laboratory. Testing can include samples of your finished products, or your formulations or raw materials, including examples of “good” (acceptable) and “bad” (reject or contaminated) products.

We will work with you to understand your measurement needs and devise an appropriate protocol. Once we receive your samples, we will determine the best options for sample preparation and measurement whether solids, liquids or vapors. After conducting the tests, we will issue a report to you on the effectiveness of our sensors and instruments to address your measurement needs. Our report will describe the instrument settings and data analysis methods utilized to provide you with an accelerated start to your own measurements in your factory or QC laboratory.

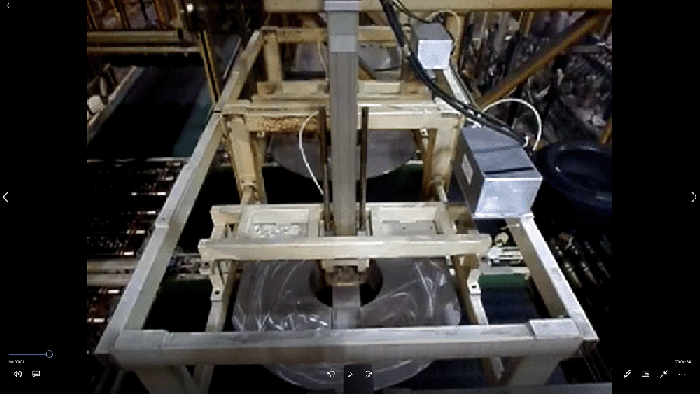

Specialized Testing for Sensor R&D

Sensigent can also prepare and test gas and vapor mixtures under a variety of conditions, including wide ranges in humidity (0-95% RH), temperature (-40oC to 200oC) and pressure, using our specialized test equipment. Tests can be designed to meet your requirements, or to develop customized sensors and customized calibrations for your most challenging applications.

Design Services for OEMs, Integration and New Products

Sensigent manufactures eNose® instruments for OEMs like our eNose Aqua product. Adaptations and customization of the eNose and MSEM 160 instruments as product platforms, and MSEM 1400 and MSEM 3200 products as platforms for production facilities and networked systems of sensors, are available readily to meet your specific sensing requirements, whether in the factory, QC laboratory or in the field. See more examples of our new product design services on our INSTRUMENTATION pages.

CONTACT US to discuss your sensing applications and how our instrumentation design services and laboratory testing services combined with our expertise in sensing applications can help you today.