Instrumentation

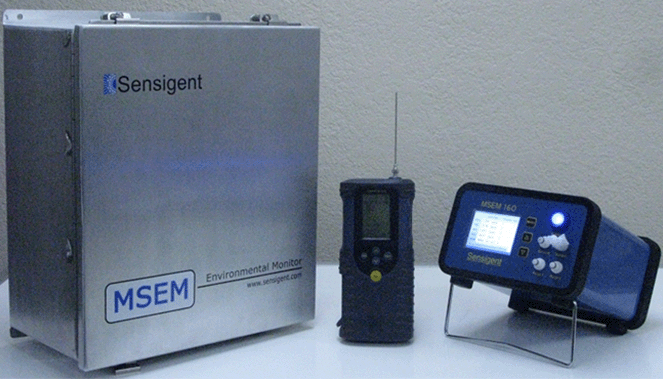

In addition to our handheld eNose (Cyranose) and chemical and odor monitor systems (MSEM), Sensigent develops custom sensor and instrumentation products for nondestructive testing and inspection for production facilities. These custom products include in-line process monitors for manufacturing systems and OEM sensors for insertion in industrial automation equipment. Our product and systems engineering expertise is complemented by our scientific expertise for application of our proprietary sensors and multivariate analysis and data fusion algorithms for turn-key inspection solutions with real-time analysis and reporting.

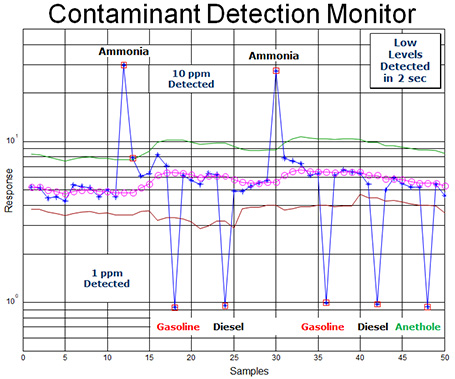

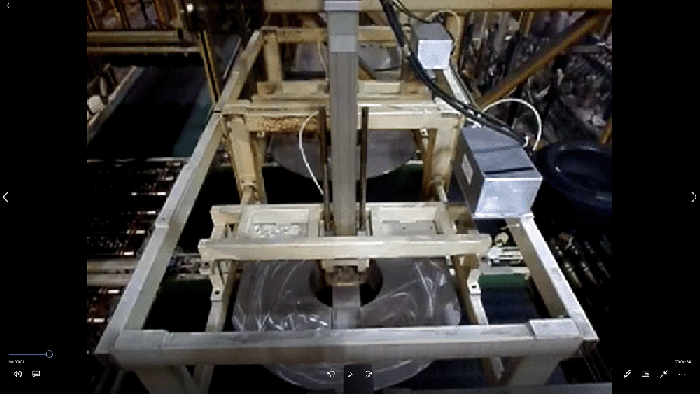

In-line Process Monitors. Our industrial process monitor solutions are based on the MSEM platform (MSEM PM) with sensors, sampling systems and communications and control interfaces designed to the requirements of the production facility. Monitors are typically placed on a stand alongside or over the production line conveyor to measure at the full line speed, or on a parallel path at a slower speed, depending on the product and the operating and measurement requirements.

Sensors for Integration. To provide the most compact, efficient and cost-effective sensing solutions, Sensigent sensing modules (eNose OEM) are incorporated directly in existing automation equipment with control and reporting provided by existing computers or programmable logic controllers (PLC) on the production line.

Sensigent instruments can be found in manufacturing facilities, industrial plants and outdoor monitoring installations worldwide, as well as QC laboratories. Sensigent can customize, modify, develop, and support your requirements in specialized applications, with custom sensing devices and turn-key systems of sensors.

CONTACT USnow to discuss your specific sensing requirements for custom in-line process monitoring solutions and custom facility and outdoor area monitors.