eNose Sensor Products for OEMs

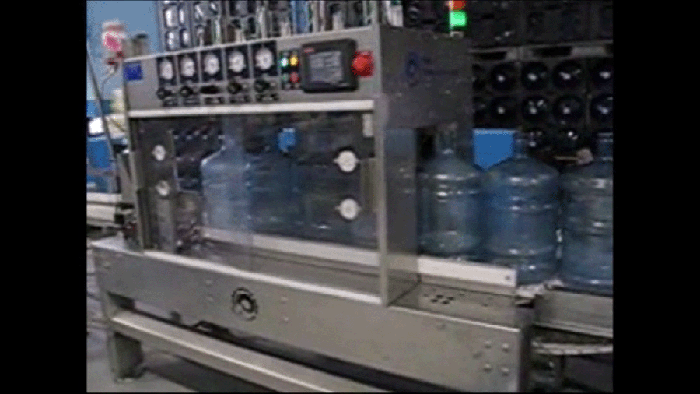

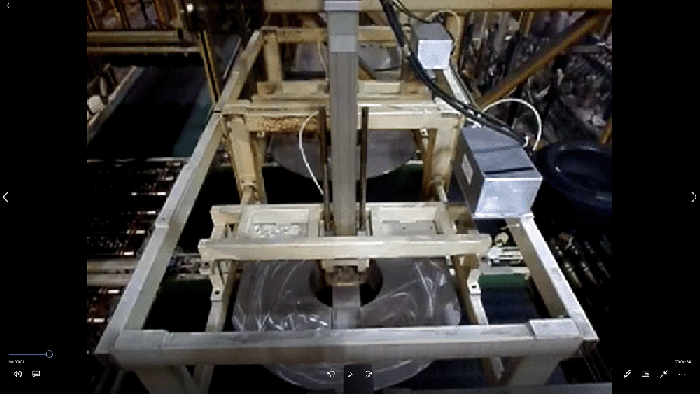

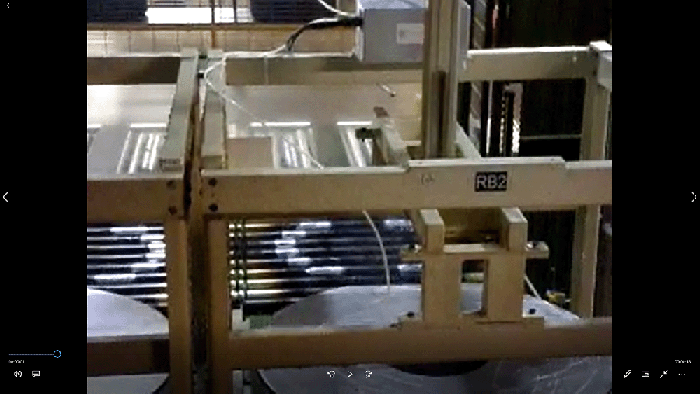

Sensigent eNose® devices are a family of OEM sensor products for nondestructive inspection, production line monitoring and process control in industrial automation systems across many industries. Each eNose sniffs continuously at moderate line speeds (to 1,800/hr) to make over 1 million sniffs per year. Here we highlight just one of our eNose® devices for OEMs in continuous operation since 2008 in bottling plants worldwide.

The eNose® Aqua OEM sensor detects contamination in refillable water bottles used in the Home Office Delivery (HOD) market segment of the $60 billion dollar global bottled water industry. The eNose® Aqua utilizes advanced nanocomposite sensor technology to provide low levels of detection (ppb to ppm) to a wide range of contaminants (including unknown compounds) with a 2-year warranty to guarantee performance for >1,000,000 measurements per year.

Detected contaminants include fuels, oils, solvents, cleaning products, flavors, additives, beverages, and miscellaneous residues and foreign materials that can affect water quality and water safety. The eNose® Aqua delivers consistent and reliable performance under harsh real world conditions and operates 24/7/365 in bottling plants throughout the world.

The eNose® QA is a handheld detector for portable sensing throughout the factory and the entire process chain. The eNose® QA is used to confirm contamination in HOD bottles rejected from the bottling line by the eNose® Aqua as well as to inspect bottles before return for cleaning/refilling and to inspect filled bottles for odors or contamination before delivery. The eNose® QA is also used for leak detection of refrigerants and hydrocarbons and to confirm cleanliness of the factory air supply.

DOWNLOAD OUR DATASHEET orCONTACT US to learn more about our eNose® sensor products for OEMs for nondestructive inspection and process monitoring.